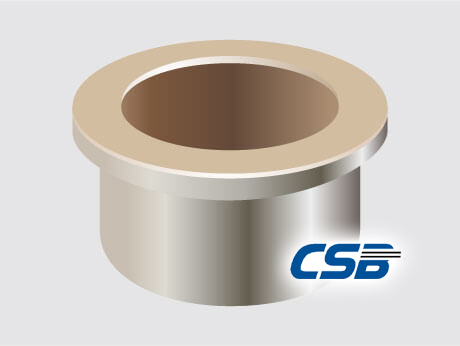

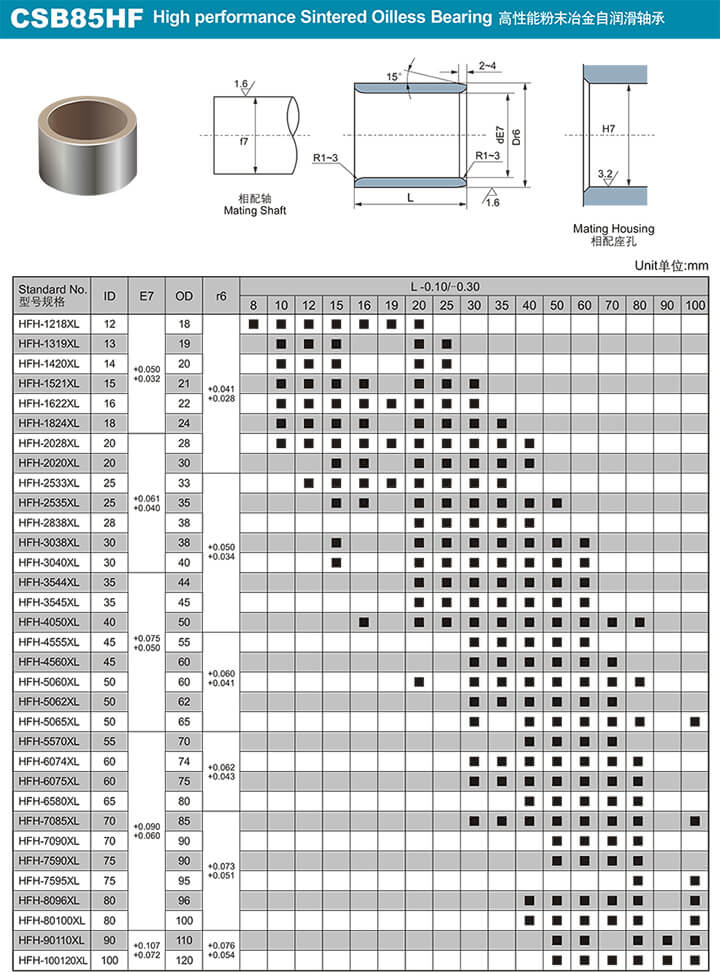

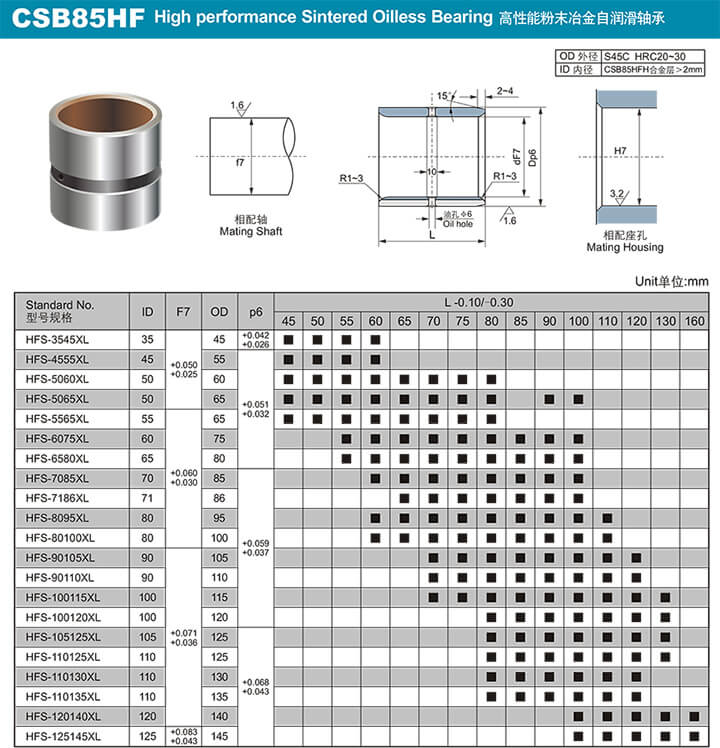

CSB85H

Powdered Metal Sintered with Solid Lubricants

Features

CSB85H Powdered Metal

self-lubricating bushings are manufacture using a sintering

process to solidify the “PM”. Suitable for high load

applications or in position where the lubricating and greasing

is hard to access thus dry operation may be needed. The optional

backing material are Bronze, Steel or Stainless steel. Depending

on the working conditions, working temperature, loading, linear

speed and environmental requirement, there are optional solid

lubricants such as graphite, MoS2. The embedded solid lubricant

structure will continuously provide a low friction working

surface to the bearing; therefore, the bearing service life is

extended considerably. Compared with the traditional sintered

parts, this material has better wear and high temperature

resistance features.

For more information on our sliding bearing

bushing materials and applications download our catalogue

“CLICK-HERE

to DOWNLOAD CATALOGUE”

You can also contact our global sales team

by sending a message online through our website

“CLICK-HERE to SEND A MESSAGE”

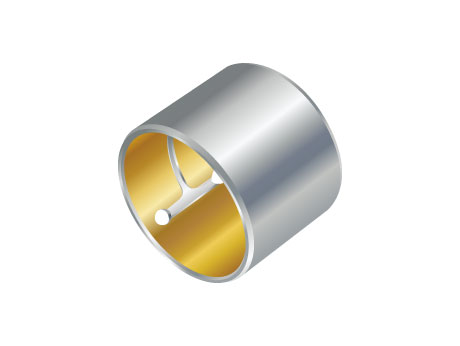

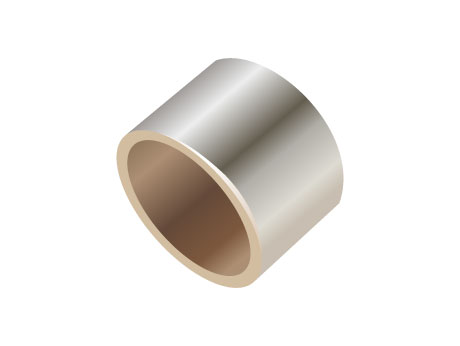

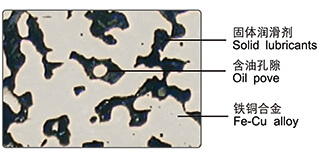

Structure

- Suitable in dry conditions, can be maintenance-free

- Has a high load capacity

- Wide temperature range -200 ℃~ +600 ℃;

- You can re-radiation environment and vacuum environment

- Material has good electrical properties, without the static phenomenon;

- Suitable in dust conditions / corrosive environments

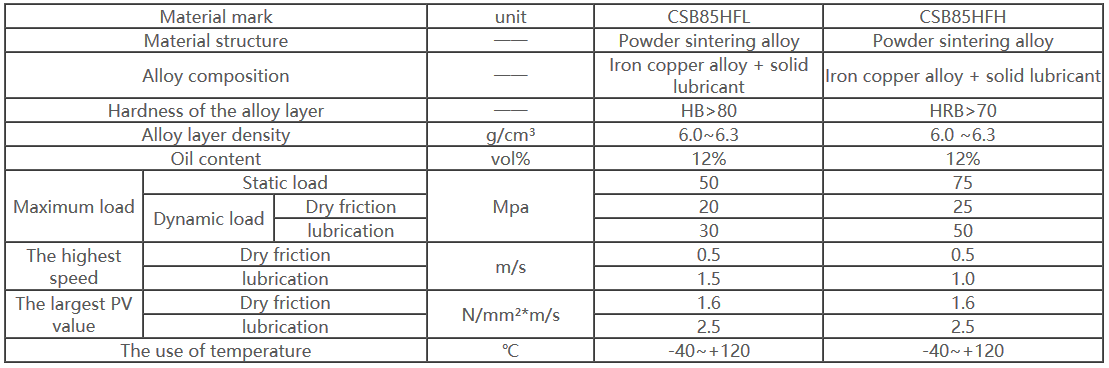

Tech. Data

Typical Applications

Joint bushes for excavator

- Rod-end bushing for hydraulic cylinder

- Link bushing for construction and heavy industry machinery, like wheel loader, dump truck, forklift, crane etc.

- Tie-bar, Cross guide bar bushes for Injection molding machinery, die casting machinery

- Industrial robot joint bushes

- Guide bushing for molding equipment

- See more about bi-metal bushing / sliding bearing applications "CLICK HERE"