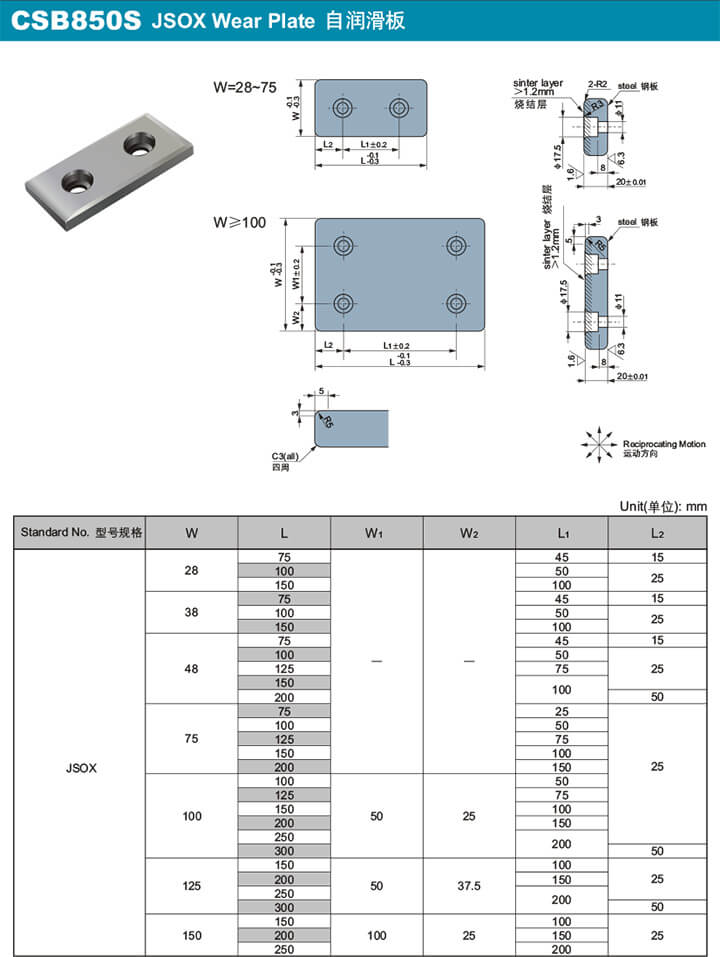

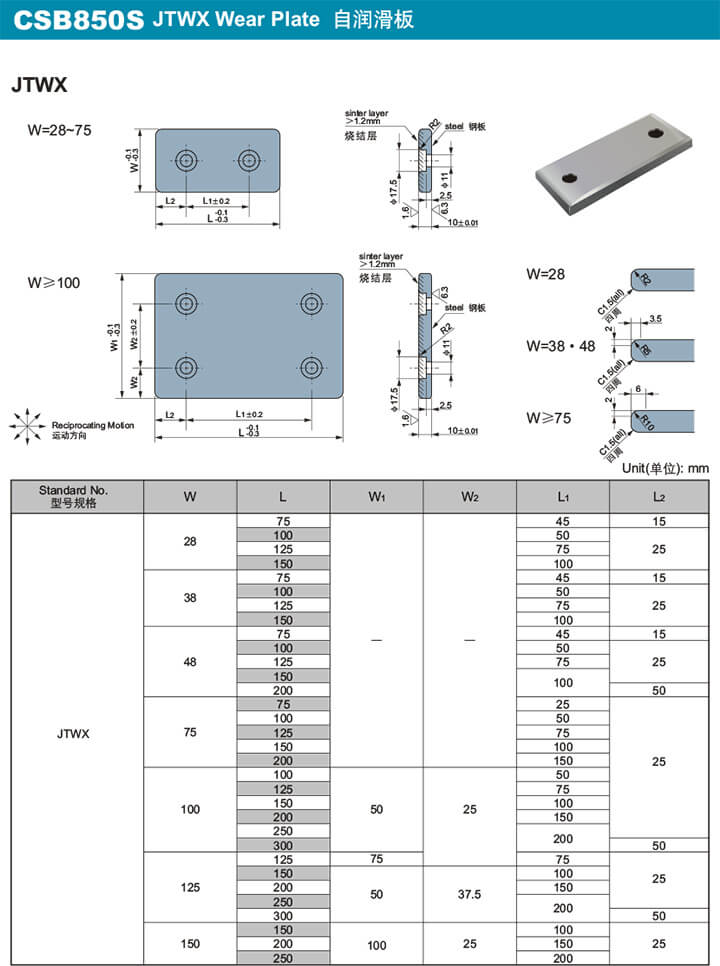

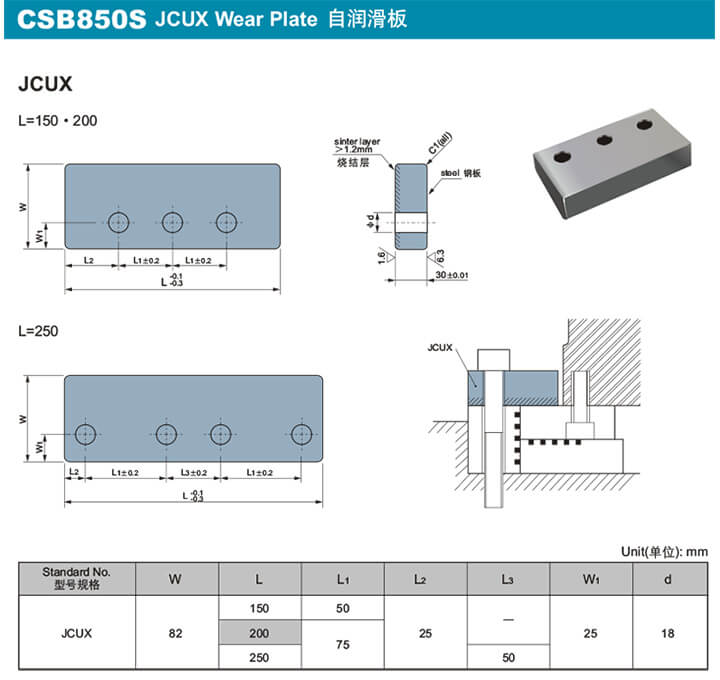

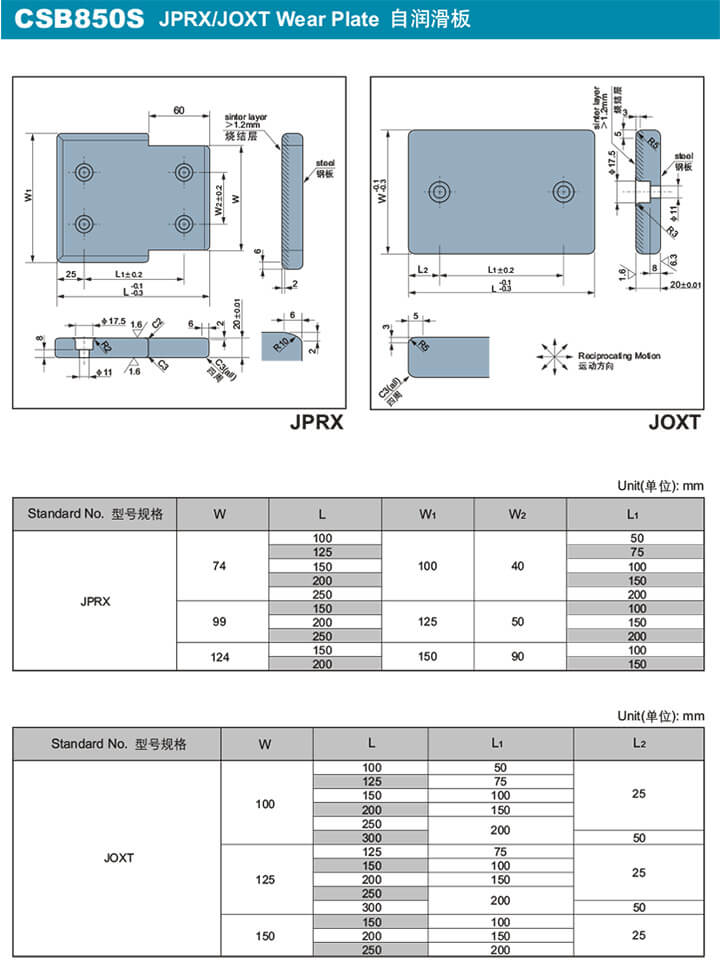

CSB850S

Bi-metal Fe-Ni Sintered Alloy with Solid Lubricants

Features

Suitability for motions of in any

direction due to its solid uniform lubricant, with high

performance even for micro-range motions. It is suitable for

self-lubrication work condition, we recommend pre-lubricated if

possible, for dry starts, future lubrication however, would be

drastically reduced. It has very good load capacity, good wear

resistance and low friction. The bearing can be machined again

after the parts fixed to achieve tighter tolerance.

For more information on our sliding bearing

bushing materials and applications download our catalogue

“CLICK-HERE

to DOWNLOAD CATALOGUE”

You can also contact our global sales team

by sending a message online through our website

“CLICK-HERE to SEND A MESSAGE”

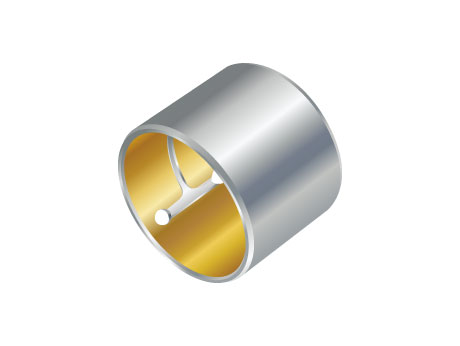

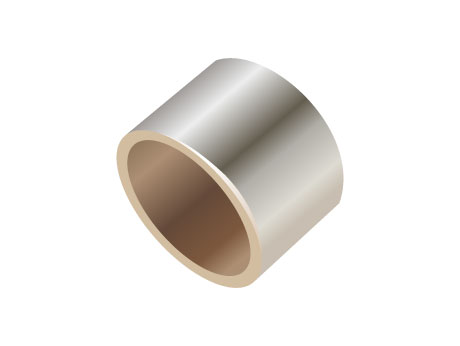

Structure

CSB850 is a solid composite multi-layer bearing composed of a special sintered material which forms the sliding surface and steel material forms the backing. Sintered layers are of a special copper-nickel alloy containing uniformly dispersed solid lubricant, the main component of which is graphite. The solid lubricants will be released at the bearing surface as wear occurs. This ensures a lower coefficient of friction during operation. In addition, these sintered layers are oil impregnated. Applications covered are automotive die wear plates, industrial robots, plastic injection moulding machine wear plates and tie-bar bearings, construction machines etc.

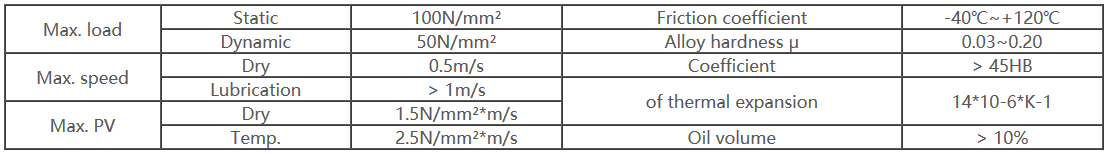

Tech. Data

Typical Applications

This material has been widely used in high load with tower friction and good wear resistance requested mechanical parts where oil given is difficult such as automotive die wear plate, industrial robots, injection wear plate, injection tie-bar bushes, construction machines self-lubricating bearings etc. See more about bi-metal bushing / sliding bearing applications "CLICK HERE"